Design For Manufacturing — The Essentials and Benefits of DFM (infographic)

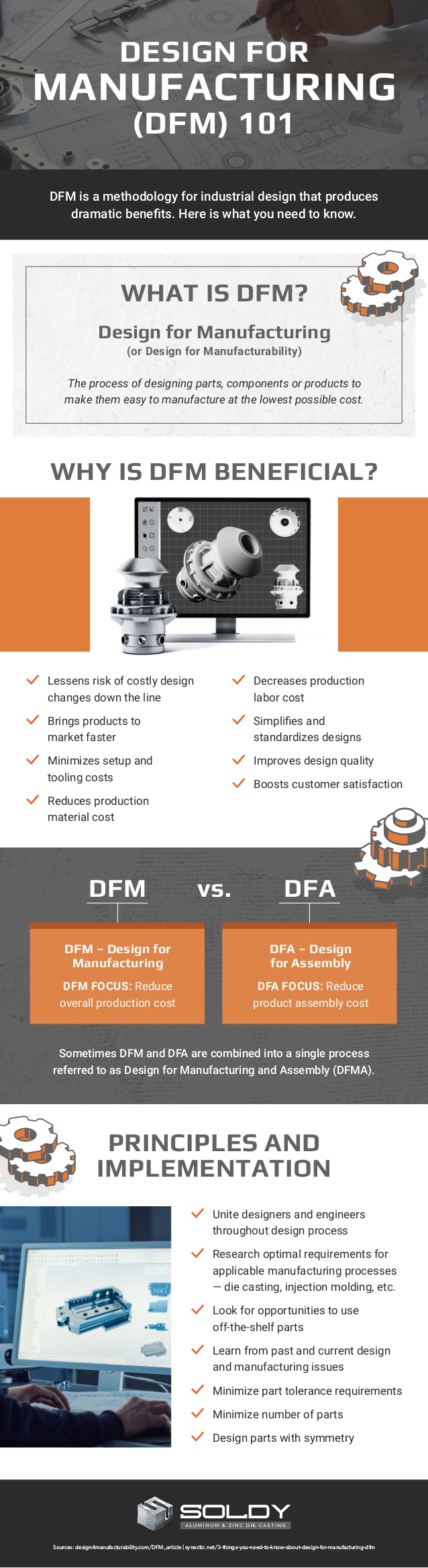

In manufacturing, working smarter is the key to reducing costs, improving quality, expanding sales and maximizing operational profitability. An important way to work smarter is by implementing a Design for Manufacturing (DFM) methodology. The accompanying resource provides an excellent overview of what DFM is, why it is so important, and how to implement it effectively.

This infographic will be helpful for anyone involved in a startup manufacturing business, or for team members of an established manufacturing business looking for ways to combat competition; bring products to market more quickly; or improve the overall quality of parts, components or products.

The fundamental idea behind DFM is to design parts for ease of manufacturing, starting at the beginning of the design process. This is a major change from the days when designers would hand designs to engineers — at which point serious problems arose because the designs were impractical (or impossible) to manufacture. The result: bogged down product development; tension between design and engineering teams; costly redesigns late in the product development process; and, worst of all, product flaws after market introduction and/or high prices driven by high production cost that limited unit sales and market penetration.

DFM is somewhat different from Design for Assembly (DFA). This point is important to consider for manufacturers involved in products requiring assembly during or after the manufacturing process.

For a more detailed analysis about Design For Manufacturing, Soldy Manufacturing has put together the essentials and benefits in this infographic:

DFM 101 infographic created by Soldy Manufacturing

Whether it is the design of your products or the layout of a new facility, USC Consulting Group can help enhance both your planning process and operational functionality. Contact us today and we can share how we put our over 50 years of experience to work for our clients to improve their planning and efficiency.